Technical Support Documentation

Download specification documentation for your GlanAir products:

Scientific Article: Air Quality in IVF Clinics

Frequently Asked Questions

Yes. The CEMS provides fully automated, continuous monitoring in line with the requirements of GMP and ISO 14644-2:2015.

Yes, data can be managed via either the HEX software, SCADA or other host application. We provide a RESTful API for real-time data transfer. There is also a facility on HEX for data export to csv.

Yes. Up to 3 years’ data storage is available. One-minute data is collected and categorised into 24 particle bins along with temperature and humidity data to enable root cause investigations and analysis of performance drift.

Each device and site is easily labelled on HEX, for example, “Cleanroom 14, Facility B”

Yes. HEX is designed for secure, remote access to multiple sites as well as site-specific local access for operational management.

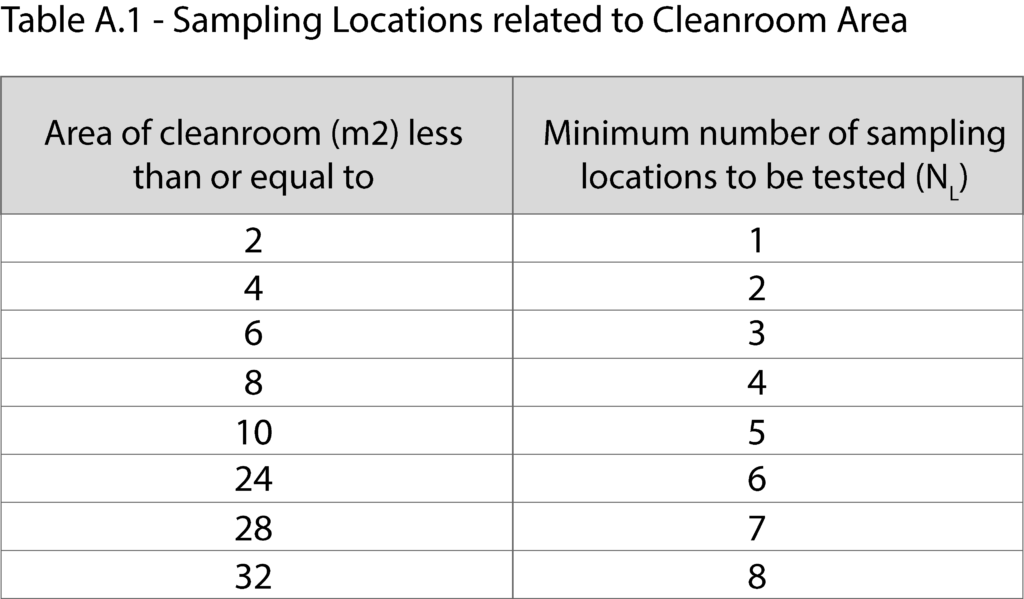

This depends upon the environment and application. For cleanroom monitoring, ISO 14644-1:2015 specifies requirements for number of sample locations as shown in the table below. Note that if the considered area falls between two values in the table, the greater of the two should be selected.

The only requirements at site are (1) power socket for each device and (2) internet access for the GlanAir gateway. The gateway connects to either an Ethernet port (recommended) or an independent GSM router with SIM. Each monitoring device is wireless with plug & play technology for connection in minutes.

Each device is pre-configured for 1-minute sampling as standard. Sampling interval can be reduced to 20 seconds if required.

Our customers depend upon instrument precision for reliable early warning of contamination threats. Our comprehensive calibration procedure is essential for precise measurement and ensuring consistent sensor performance. All sensors are tested in our customised, air-tight cleanroom chamber at the NuWave Sensors factory, carried out under consistent temperature, humidity and airflow conditions. A 3-yr Service Pack is recommended for annual calibration with easy sensor swap-out.

The CEMS provides an immediate alert to trigger action when thresholds are breached. For most cleanrooms alerts are generally infrequent. During the initial monitoring period, the CEMS can help users identify cleanroom process refinements to eliminate sources of contamination and therefore reduce alert frequency.

The real-time alert enables immediate remedial action in line with the user’s SOP. These typically include cleanroom inspection, HEPA operation check and door closure checks.

No. The system can be set up and operated by non-technical personnel.

The GlanAir CEMS monitors total particles. For details of our patented system for viable particle monitoring, visit lum-air.com.

The GlanAir CEMS is a proven cleanroom monitoring system utilising highly reliable but cost-effective technology developed by NuWave Sensors. As such, the CEMS can be deployed without major investment. Purchase of particle counters includes full software license, data hosting and API (i.e. no subscription fees). See our cleanroom case study for further details or complete the request a quote form.